Add:Daqiuzhuang Industrial Area,Jinghai County,Tianjin,China

Tel:08618322290777

Quote Now

Solutions for Your Industry, Ready for Your Choice

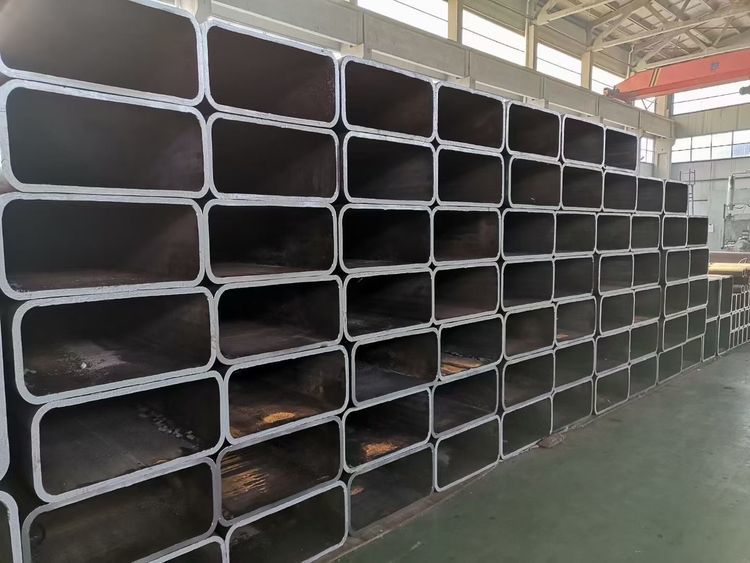

EN 10210 S460NH HOLLOW SECTIONS

- Commodity name: EN 10210 S460NH HOLLOW SECTIONS

keyword:

Details

- 产品描述

-

EN 10210-1 Grade S460NH Specification

EN 10210-1 Grade S460NH Carbon Steel Seamless Pipes and Tubes are are mild steel pipes and tubes which are low-cost Low Carbon Steel Pipes and Tubes with maximum 020 % carbon content with combination of 100-170 % manganese easy to form and shape.These pipes are manufactured as per EN specification and are commercially known as CS pipes or MS pipes.

BRISK STEEL is manufacturer and Supplierand Exporter of EN 10210-1 Grade S460NH Pipes & Tubes.

EN 10210-1 Grade S460NH Properties

Chemical Properties

Carbon Silicon Manganese Phosphorous Sulphur Molybdenum Nickel Chromium Copper Others max 0.20 max 0.60 1.00-1.70 0.035 0.03 max 0.10 max 0.80 max 0.30 max 0.70 V max 0.05 Al min 0.020 Nb max 0.05 Ti max 0.03 Mechanical Properties

Yield Strength

Tensile Strength

Elongation A5 min

MPa min ksi min MPa min MPa min ksi min Percentage 550 720 – 17 Equivalent Designation

DIN EN BS NFA ASTM ASME DIN (17123/24/25) Grade FGS 47 EN 10210-1 Grade S460NH NFA A 36-2011) Grade E 460 R+FP ASTM A 678 Grade C ASME SA 678 Grade C – EN 10210-1 Grade S460NH European standard covers specialized conveyance conditions for hot formed or annealed hollow sections from construction steel. Pipe will be supplied in 5-7 metre arbitrary lengths with butt-weld ends and varnished to stay away from oxidation of the steel when in storage. All pipes are fully certified and traceable with heat numbers hard stamped onto each random length. Trio Steel can supply cut lengths; long pieces and even bore from forged, machined bar to fulfill your urgent demand.

Dimensional Tolerances of EN 10210-1 Grade S460NHOD/Wall tolerance

Outer diameter and wall Thickness Execution

Size Range

OD Tolerance

Wall tolerance

Hot-rolled Tube OD – 80 mmOD; 80 mmWall ± 0.4 mm± 0.5 % of OD ± 0.7 mm± (5 % x wallthickness + 0.1 mm Hot-rolled peeled tube All sizesWall + 0.25/- 0 mm ± 0.8 mm± (5 % x wall thickness+ 0.2 mm) Cold Worked tubecold-rolled or cold-drawn OD 80 Wall Thickness 8 + 0.30/- 0 mm*+ 0.35/- 0 mm*+ 0.40/- 0 mm* ± 0.30 mm± 0.35 mm± 0.40 mm Straightness

The maximum deviation from the straight line is 1 mm on a gauge length of 1000 mm.Ovality

The maximum out-of-roundness is 65% of the total outer diameter tolerance.Standard length tolerances

Component length (mm)

OD 30-100 mm

OD 100-254 mm

10-100 + 1.0/- 0 + 2.0/- 0 100-600 + 2.0/- 0 + 3.0/- 0 600-1200 + 3.0/- 0 + 4.0/- 0 1200-5000 + 5.0/- 0 + 6.0/- 0 Delivery Executions of EN 10210-1 Grade S460NH

Tube EndsAll tubes are provided with spotless, square cut ends.Chamfering can be done on demand.

Tube surface

Tubes are supplied without anti-corrosive treatment, but anti-corrosive treatment is available and can be done on request.

Protection

Black and Bare

External Varnished with Black or Clear LAcquer

Mill test certificateMTC is issued in accordance with EN 10204.

PackagingTubes are packaged as standard, with steel straps into hexagonal bundles with one end flush. Tubes can also be bundled in multiples. Bundle weights are adjusted as requested by the customer. Each package contains tubes from a single cast/heat only.

Marking

Every tube is set apart with tube type, heat number, steel grade and size. Information is repeated along the whole length of the tube. Bundles are also labeled with a tag having information in both alphanumeric and by bar code.

Labelling

Material conveyed directly from our plant is labeled in accordance with automotive standard, ie with both alphanumeric and bar code information. Client particular information can be included on demand.

Core Advantage

Brisk Steel Group is rooted in a culture of "technology as the backbone, quality as the soul, and customers as the heart." Through relentless innovation, global expansion, and a commitment to responsibility, we strive to become a trusted global partner and a technological benchmark in the steel manufacturing industry.

Craftsmanship with Precision

We adhere to a rigorous quality control system that spans the entire production process—from raw material procurement and manufacturing to product delivery—ensuring the highest standards of excellence.

Innovation-Driven Technological Leadership

We prioritize R&D and technological advancement, integrating cutting-edge production lines (e.g., JCOE large-diameter LSAW pipe production) and expert teams from countries like Germany and the Netherlands to maintain our position at the forefront of the industry.

Globalization and Open Collaboration

Actively engaging in the global supply chain, we have obtained international certifications such as CE marking, enabling our products and services to reach worldwide markets.

Professional Team and Talent Empowerment

We value the recruitment and development of technical talent, building an international and professional team that drives continuous growth.

Previous:

Message

* Please keep your phone open, we will get in touch with you in time, or you can call us directly