Add:Daqiuzhuang Industrial Area,Jinghai County,Tianjin,China

Tel:08618322290777

Quote Now

Solutions for Your Industry, Ready for Your Choice

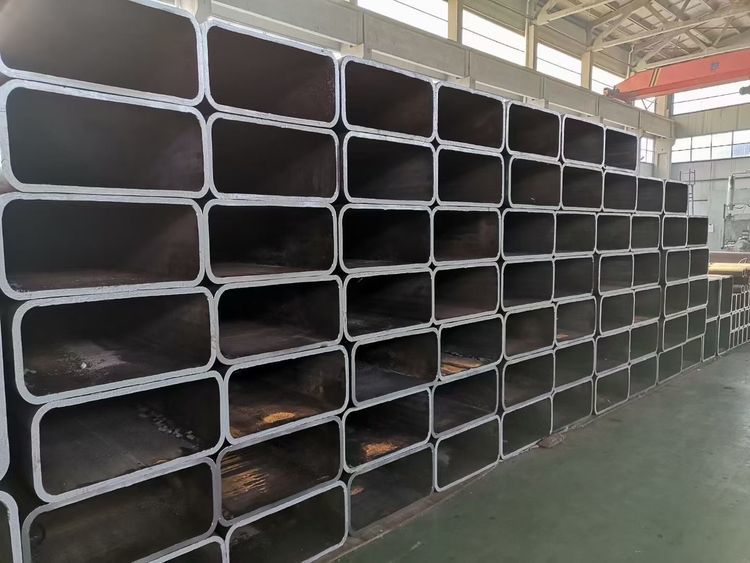

EN 10210 S460NH HOLLOW SECTIONS

- Commodity name: EN 10210 S460NH HOLLOW SECTIONS

keyword:

Details

- 产品描述

-

EN 10210-1 Specification is for Hot finished structural hollow sections of non-alloy and fine grain steels

EN 10210 standard has 3 parts, they are:

EN 10210 Part 1: Technical delivery conditions

EN 10210 Part 2: Tolerances, dimensions and sectional properties

EN 10201 Part 3: Technical delivery conditions for high strength and weather resistant steels

EN 10210-1 Hollow Section Mian Grades:

S355J0H, S355J2H, S355NH, S355NLH, S460NH, S460NLH.

EN 10210-1 Hollow Section Size:

Circular Hollow Section Dimensions: O.D 21.3-1420mm W.T 2.3-60mm

Square Hollow Section Dimensions: O.D 40*40mm-1200*1200mm W.T1.5-60mm

Rectangular Hollow Section Dimensions: O.D 50*30-1200*1000mm W.T 2.6--60mm

Application:

Steel structures, steel buildings, bridges, railway stations, airports, bus stations. stadiums.

EN 10210-1 Chemical Composition:

Table A.1 — Chemical composition — Cast analysis for product thickness≤120 mm

Steel grade

Type of deoxidationa

% by mass, maximum

C

Specified thickness (mm)

Si

Mn

P

S

N b c

Steel name

Steel number

£ 40

>40 £ 120

S235JRH

1.0039

FN

0,17

0,20

—

1,40

0,040

0,040

0,009

S275J0H

1.0149

FN

0,20

0,22

—

1,50

0,035

0,035

0,009

S275J2H

1.0138

FF

0,20

0,22

—

1,50

0,030

0,030

—

S355J0H

1.0547

FN

0,22

0,22

0,55

1,60

0,035

0,035

0,009

S355J2H

1.0576

FF

0,22

0,22

0,55

1,60

0,030

0,030

—

S355K2H

1.0512

FF

0,22

0,22

0,55

1,60

0,030

0,030

—

a The deoxidation methods are designated as follows: FN = Rimming steel not permitted

FF = Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al, or 0,015 % soluble Al).

b It is permissible to exceed the specified values provided that for each increase of 0,001 % N the P max. content is also reduced by 0,005 %. The N content of the cast analysis, however, shall not be more than 0,012 %.

c The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document.

Table B.1 — Chemical composition — Cast analyses for product thickness ≤65 mm

Steel grade

Type of deoxidationa

Sub groupb

% by mass

Steel name

Steel number

C

max.

Si

max.

Mn

P

max.

S

max.

Nb max.

V

max.

Al total c

min.

Ti max.

Cr max.

Ni max.

Mo max.

Cud

max.

N max.

S275NH

1.0493

GF

QS

0,20

0,40

0,50

1,40

0,035

0,030

0,050

0,08

0,020

0,03

0,30

0,30

0,10

0,35

0,015

S275NLH

1.0497

0,030

0,025

S355NH

1.0539

GF

QS

0,20

0,50

0,90

1,65

0,035

0,030

0,050

0,12

0,020

0,03

0,30

0,50

0,10

0,35

0,020

S355NLH

1.0549

0,18

0,030

0,025

S420NH

1.8750

GF

SS

0,22

0,60

1,00

1,70

0,035

0,030

0,050

0,20

0,020

0,03

0,30

0,80

0,10

0,70

0,025

S420NLH

1.8751

0,030

0,025

S460NH

1.8953

GF

SS

0,22

0,60

1,00

1,70

0,035

0,030

0,050

0,20

0,020

0,03

0,30

0,80

0,10

0,70

0,025

S460NLH

1.8956

0,030

0,025

a The deoxidation method is designated as follows:

GF = fully killed steel containing nitrogen binding elements in amounts sufficient to bind the available nitrogen and having a fine grain structure.

b QS = quality steel. SS = special steel.

c If sufficient N-binding elements are present, the minimum total Al content does not apply.

d If the copper content is greater than 0,30 % then the nickel content shall be at least half of the copper content.

Table A.2 — Maximum carbon equivalent value (CEV) based on cast analysis a

Steel grade

Maximum CEV in % for specified thicknesses in mm

Steel name

Steel number

£ 16

> 16

£ 40

> 40

£ 65

> 65

£ 120

S235JRH

1.0039

0,37

0,39

0,41

0,44

S275J0H

1.0149

0,41

0,43

0,45

0,48

S275J2H

1.0138

0,41

0,43

0,45

0,48

S355J0H

1.0547

0,45

0,47

0,50

0,53

S355J2H

1.0576

0,45

0,47

0,50

0,53

S355K2H

1.0512

0,45

0,47

0,50

0,53

a See 6.5.2, Option 1.2.

Table B.2 — Maximum carbon equivalent value based on cast analysis

Steel grade

Maximum CEV for specified thicknesses

mm

Steel name

Steel number

£16

>16 £65

S275NH

S275NLH

1.0493

1.0497

0,40

0,40

S355NH

1.0539

0,43

0,45

S335NLH

1.0549

S420NH

1.8750

0,50

0,52

S420NLH

1.8751

S460NH

1.8953

0,53

0,55

S460NLH

1.8956

EN 10210-1 Mechanical Property:

Table A.3 — Mechanical properties of non-alloy structural steel hollow section

Steel grade

Min. yield strength

ReH MPa

Tensile strength

Rm MPa

Min. elongation

A a b %

Minimum impact

energy KV d J

Specified thickness

mm

Specified thickness

mm

Specified thickness

mm

At test temperature

of

Steel

name

Steel

number

£16

>16

£40

>40

£63

>63

£80

>80

£100

> 00

£120

£3

>3

£100

>100

£120

£ 40

>40

£63

>63

£100

>100

£120

-20°C

0°C

20°C

S235JRHc

1.0039

235

225

215

215

215

195

360-510

360-510

350-500

26

25

24

22

-

-

27

S275J0Hc

1.0149

275

265

255

245

235

225

430-580

410-560

400-540

23

22

21

19

-

27

-

S275J2H

1.0138

27

-

-

S355J0Hc

1.0547

355

345

335

325

315

295

510-680

470-630

450-600

22

21

20

18

-

27

-

S355J2H

1.0576

27

-

-

S355K2H

1.0512

40 e

-

-

a Longitudinal values. Transverse values are 2 % lower.

b For thicknesses < 3 mm, see 9.2.2.

c The impact properties are verified only when Option 1.3 is specified.

d For impact properties for reduced section test pieces see 6.6.2.

e This value corresponds to 27J at –30 °C (see EN 1993-1-1).

Table B.3 — Mechanical properties of fine grain structural steel hollow sections

Steel grade

Min. yield strength ReH

MPa

Tensile strength

Rm MPa

at specified

thickness

65 mm

Minimum elongation A

%

at specified thickness £ 65 mm

Minimum impact energy KVa J

Steel name

Steel number

Specified thickness

mm

At test temperature of

£ 16

> 16

£ 40

> 40

£ 65

Longitudinal

Transverse

-50 °C

-20°C

S275NH

1.0493

275

265

255

370–510

24

22

-

40 b

S275NLH

1.0497

27

-

S355NH

1.0539

355

345

335

470–630

22

20

-

40 b

S355NLH

1.0549

27

-

S420NH

1.8750

420

400

390

520—680

19

17

-

40 b

S420NLH

1.8751

27

-

S460NH

1.8953

460

440

430

540–720

17

15

-

40 b

S460NLH

1.8956

27

-

a For impact properties for reduced section test pieces, see 6.6.2.

b This value corresponds to 27J at –30 °C (see EN 1993-1-1).

Core Advantage

Brisk Steel Group is rooted in a culture of "technology as the backbone, quality as the soul, and customers as the heart." Through relentless innovation, global expansion, and a commitment to responsibility, we strive to become a trusted global partner and a technological benchmark in the steel manufacturing industry.

Craftsmanship with Precision

We adhere to a rigorous quality control system that spans the entire production process—from raw material procurement and manufacturing to product delivery—ensuring the highest standards of excellence.

Innovation-Driven Technological Leadership

We prioritize R&D and technological advancement, integrating cutting-edge production lines (e.g., JCOE large-diameter LSAW pipe production) and expert teams from countries like Germany and the Netherlands to maintain our position at the forefront of the industry.

Globalization and Open Collaboration

Actively engaging in the global supply chain, we have obtained international certifications such as CE marking, enabling our products and services to reach worldwide markets.

Professional Team and Talent Empowerment

We value the recruitment and development of technical talent, building an international and professional team that drives continuous growth.

Previous:

Message

* Please keep your phone open, we will get in touch with you in time, or you can call us directly