Add:Daqiuzhuang Industrial Area,Jinghai County,Tianjin,China

Tel:08618322290777

Quote Now

Solutions for Your Industry, Ready for Your Choice

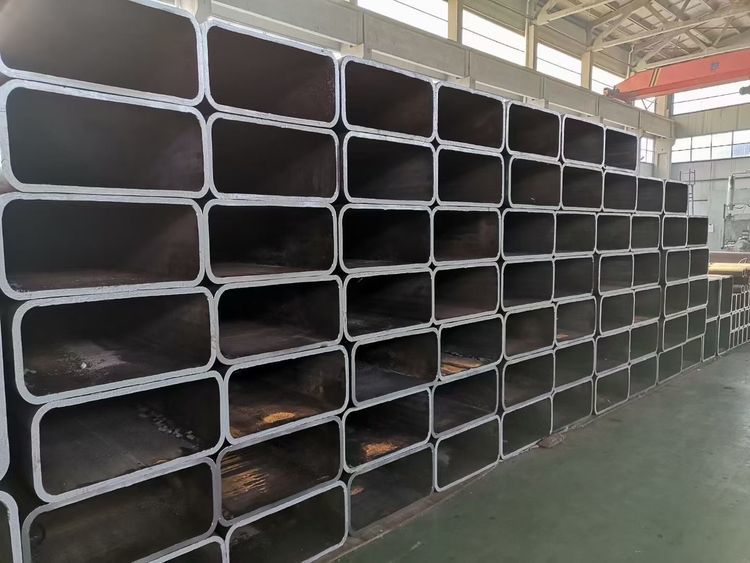

EN 10219 STRUCTURAL HOLLOW SECTIONS

- Commodity name: EN 10219 STRUCTURAL HOLLOW SECTIONS

keyword:

Details

- 产品描述

-

EN 10219-1 Specification is for Cold-formed Welded Structural Hollow Sections of Non-alloy and Fine Grain Steels

Cold forming

Cold-formed hollow sections are manufactured through the continuous forming at room temperature of a steel strip passing through forming stands that progressively bend it into a circular shape. This circular shape then enters a welding stand that joins the strip edges together in a continuous longitudinal weld seam. After the welding station, the outside seam of the circular tube is removed, and the final shape (Circular, Square, Rectangular) and precise dimensions of the tube are achieved by passing it through sizing stands.

A cutting saw then divides the length of the welded tube into standard or customised lengths as required.Weld seams are ensured via electromagnetic NDT inspection.

These products meet all of the EN 10219-1 standard requirements.

Garde:S235JRH,S275J0H,S275J2H,S355J0H,S355J2H,S355K2H S460NH S550 S690

Type: Cold-fromed (ERW)

Circular Hollow Section:

OD: 21.3-1420mm WT: 2-60mm

Square Hollow Section:

OD: 20 X 20 - 1200 X 1200mm WT: 2-60mm

Rectangular Hollow Section:

OD: 40 X 20 - 1200 X 1000mm WT: 2-60mm

Core Advantage

Brisk Steel Group is rooted in a culture of "technology as the backbone, quality as the soul, and customers as the heart." Through relentless innovation, global expansion, and a commitment to responsibility, we strive to become a trusted global partner and a technological benchmark in the steel manufacturing industry.

Craftsmanship with Precision

We adhere to a rigorous quality control system that spans the entire production process—from raw material procurement and manufacturing to product delivery—ensuring the highest standards of excellence.

Innovation-Driven Technological Leadership

We prioritize R&D and technological advancement, integrating cutting-edge production lines (e.g., JCOE large-diameter LSAW pipe production) and expert teams from countries like Germany and the Netherlands to maintain our position at the forefront of the industry.

Globalization and Open Collaboration

Actively engaging in the global supply chain, we have obtained international certifications such as CE marking, enabling our products and services to reach worldwide markets.

Professional Team and Talent Empowerment

We value the recruitment and development of technical talent, building an international and professional team that drives continuous growth.

Previous:

Message

* Please keep your phone open, we will get in touch with you in time, or you can call us directly